A Itaipu power plant, located on the border between Brazil and Paraguay, is the undisputed global leader in clean and renewable energy generation.

Therefore, although it does not have the largest installed capacity when compared to other hydroelectric plants, this binational enterprise has the largest energy production in the world.

As a result, it plays a super important role in providing sustainable energy for both countries.

Furthermore, the Itaipu plant contributes greatly to:

Therefore, the Itaipu Hydroelectric Plant is a milestone in the history of global energy, demonstrating that it is possible to meet society's energy needs in a responsible and ecologically conscious way.

Discover the grandeur of the Itaipu Plant: Get your ticket now and experience a unique experience!

In addition to the notable production of clean energy, the Itaipu power plant It also stands out for its social and environmental responsibility initiatives in Foz do Iguaçu.

Thus, Itaipu Binacional is an exemplary reference, playing a fundamental role in regional development, preserving the environment and promoting equal opportunities in the region.

Its actions range from biodiversity protection in the surrounding area until child and adolescent protection programs, promoting activities of professional training, sport, culture, education and much mores.

Therefore, Itaipu exemplifies a sustainability model that brings benefits to both Brazil and Paraguay, while also promotes positive impacts on a global scale.

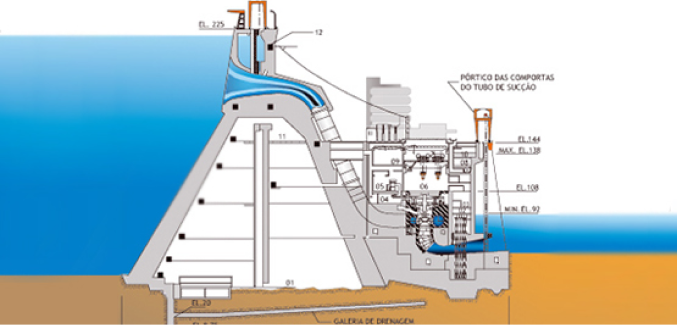

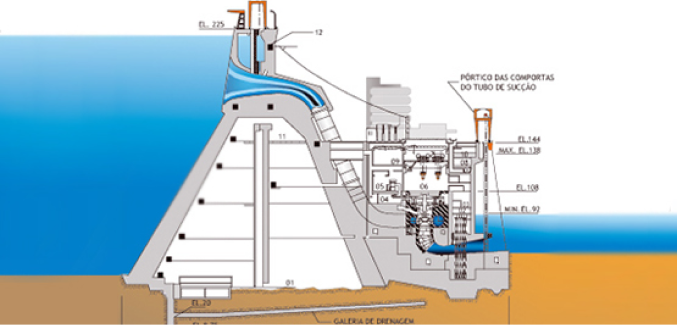

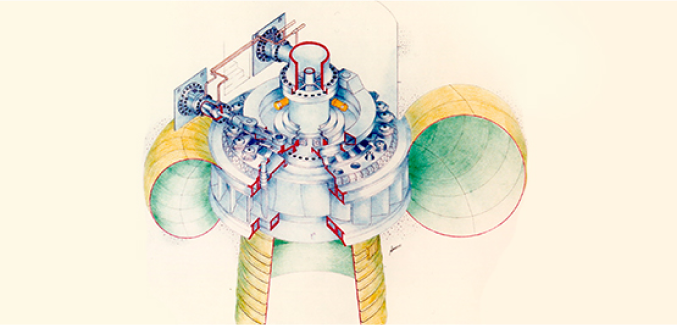

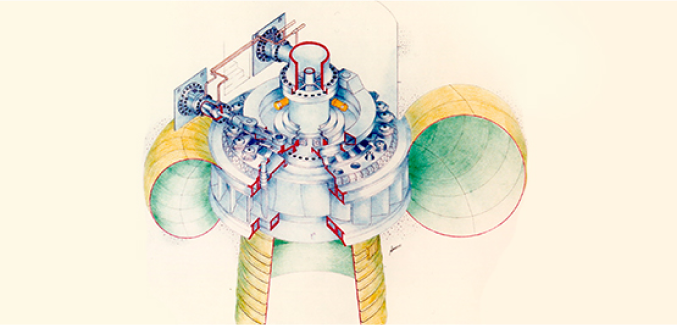

The Itaipu Plant generates energy through hydraulic energy, taking advantage of the gravitational potential energy of water retained in an elevated dam.

This energy is converted into kinetic energy through turbines, which consist of wheels with blades turned by water.

Then, a generator transforms the rotational movement of the turbine into electricity.

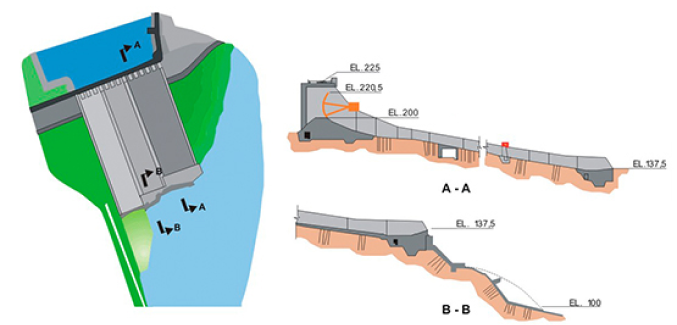

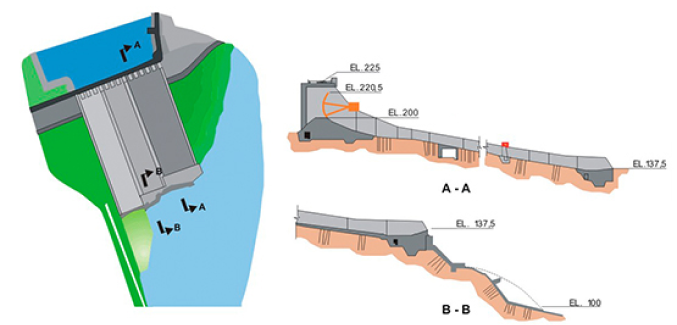

The plant's dam creates the level difference necessary to activate the turbines, directing part of the water to the penstocks and, when there is excess water, the rest flows through the spillway back to the river.

The powerhouse houses the electrical generation equipment, where the rotation of the turbines generates electricity through the generator.

In other words, the studies indicated the best construction site for the Plant in order to take advantage of the 120 m difference in level.

Then, the river was dammed to form the lake, and the water, when falling 120 m, moves the turbines which, in turn, produce electricity.

Thus, each penstock (white tube) passes 700m2 of water per second.

Check out the technical data of the Itaipu Plant:

The dam is the structure (concrete, rockfill and earth) that serves to contain the water and obtain the 120m difference in level (nominal gross head) that allows the turbines to operate.

In the upper part of the main dam, there are water intakes, structures with gates that allow the water, passing through them and through the penstocks, to reach the spiral box, where it turns the turbine.

The spillway has the function de discharge all water not used for generation.

The spillway's maximum discharge capacity is 62,2 m3/s – 40 times higher than the average flow of the Iguaçu Falls -. The maximum probable flood inflow into the reservoir, used for its project, is 72.020 m3/s.

The Itaipu Hydroelectric Plant mainly supplies South, Southeast and Central-West regions of Brazil (in addition to a part of Paraguayan territory).

In this way, it provides electricity to a significant part of the states in these regions, contributing to the supply of electricity to urban and industrial areas, benefiting millions of people and companies.

The Itaipu Hydroelectric Plant won several awards over the years, standing out for its excellence in sustainable tourism and technological innovation.

Among the awards received are:

Furthermore, Itaipu received recognition such as ISO 9001: 2015 since 2012 and won the Braztoa Sustainability Award (2015).

These awards attest to the plant's commitment to sustainability and quality in its tourist operations.

The volume of concrete used in the construction of the hydroelectric plant (12,7 million m³) would be enough to build 210 football stadiums the size of Maracanã, in Rio de Janeiro.

The maximum flow of the Itaipu spillway (62,2 thousand cubic meters per second) is 40 times higher than the average flow of the Iguaçu Falls (1.500 cubic meters per second).

The amount of iron and steel used would make it possible to build 380 Eiffel Towers.

1.350 km² is the size of the lake formed by the Itaipu reservoir, an area larger than the entire urban area of the city of São Paulo.

24 million native tree seedlings were planted in the reservoir's protection strip. It was the largest reforestation of its kind in the world.

40 thousand workers participated in the construction of the plant at the height of the works.

The height of the main dam (196 meters) corresponds to the height of a 65-story building.

The flow of the plant's two turbines (700 cubic meters of water per second each) is equivalent to the average flow of the Iguaçu Falls, both wonders located in Foz do Iguaçu

In a single day, November 14, 1978, Itaipu broke a South American record during the concreting of the dam, when 7.207 cubic meters of concrete equivalent to a ten-story building were poured into the project every hour. Or 24 buildings in the same day.

The largest hydroelectric plant in Brazil is the Belo Monte Hydroelectric Plant, located on the Xingu River, in the state of Pará.

With an installed capacity of approximately 11.233 megawatts (MW), it is one of the largest in the world in terms of power.

The largest hydroelectric plant in the world is the Three Gorges Hydroelectric Power Plant, located on the Yangtze River in China, with an installed capacity of around 22.500 megawatts (MW).

In addition to providing a significant amount of clean, renewable energy, the Three Gorges Power Plant also contributes to flood control and navigation on the Yangtze River.

The Itaipu Hydroelectric Plant is extremely important for several reasons.

Firstly, it is one of the largest sources of clean and renewable energy in the world, contributing significantly to the electricity supply in Brazil and Paraguay.

Furthermore, it plays a fundamental role in regulating the Paraná River, preventing floods and ensuring the supply of water for various activities.

In fact, Itaipu also promotes regional development, promoting tourism and social programs, and is also an example of successful binational cooperation, strengthening relations between Brazil and Paraguay.

The Itaipu Plant generates electricity using the power of water. Thus, it dams the water in an artificial lake, creating potential energy.

The water is released and flows through the turbine, which rotates, transforming the water's energy into kinetic energy.

Then, a generator converts this kinetic energy into electricity. Additionally, the dam creates a waterfall to drive the turbine.

Finally, the excess water passes through gates called spillways, and all of this happens in the powerhouse, where electricity is produced.

The history of the Itaipu Hydroelectric Plant dates back to the 60s, when Brazil and Paraguay began discussing the idea of taking advantage of the hydraulic potential of the Paraná River.

In 1973, both countries signed the Itaipu Treaty, outlining the terms for the construction of the plant.

Work began in 1975, involving consortiums of companies from both sides of the border.

The construction of the plant was a monumental engineering challenge and involved thousands of workers.

In 1984, Itaipu began generating energy, becoming one of the largest plants in the world.

Therefore, its operation benefits Brazil and Paraguay economically and also contributes to the generation of clean and renewable energy.

The Itaipu Hydroelectric Plant is located on the border between Brazil and Paraguay, in the southern region of Brazil, in the state of Paraná.

The construction of the Itaipu Hydroelectric Plant lasted approximately 10 years.

Discover the construction phases:

The construction of the Itaipu Hydroelectric Plant was carried out by consortia of Brazilian and Paraguayan companies.

Thus, the civil construction works were carried out by the Unicon (Brazilian) and Conempa (Paraguayan) consortiums.

On the other hand, the electromechanical assembly works were carried out by the consortiums Itamon (Brazilian) and CIE (Paraguayan).

These consortia involved several companies, including Cetenco Engenharia Ltda., Camargo Corrêa, Andrade Gutierrez, among others (on the Brazilian side); and Paraguayan companies such as A Barrail Hermanos, ECCA SA and others on the Paraguayan side.

FUNDACAO PARQUE TECHNOLOGICO ITAIPU – BRAZIL

CNPJ 07.769.688.0001-18

Visitor Reception Center Av. Tancredo Neves, 6702

Foz do Iguaçu, PR 🇧🇷

“The Itaipu Technological Park Foundation – Brazil, in compliance with the General Personal Data Protection Law 13.709/2018), clarifies that all documents received by the Itaipu Tourist Complex – Brazil will be used exclusively in the registration process, as provided for in said Law. By providing the data, the visitor is aware and authorizes that the personal data contained in the system will be processed and made available to third parties for the sole purpose of proving the identity of the holder, for the time necessary for the aforementioned purposes.”